Battery unit manufacturing

2.1 Positive and negative electrode preparation

First, the positive electrode and the negative electrode materials are mixed with the conductive agent and the binder respectively to form a slurry. Then the slurry is coated on metal foil (usually aluminum foil and copper foil), and the positive and negative electrode sheets are formed through drying, calendering and other processes.

2.2 Diaphragm assembly

Insert a diaphragm between the positive and negative electrode sheets to ensure safe isolation within the battery.

2.3 Winding or stacking

The positive and negative electrode sheets and the separator are wound into a battery cell or stacked into a layered structure in a certain order.

2.4 Packaging

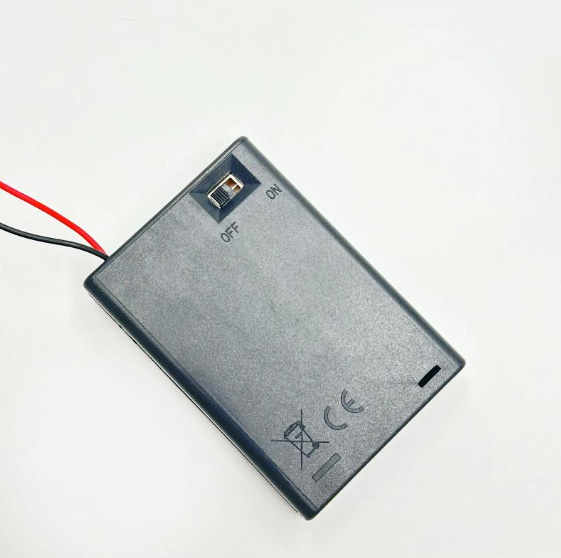

The wound or stacked battery cell is placed into the casing, injected with electrolyte, and then sealed to form a battery cell.

https://www.custom-battery-packs.com:Custom Battery Packs Battery Packs Custom Batteries

目录 返回

首页